Custom Applications

Our experts can create any tool you may need to properly perform your daily machining procedures. We’ll take a look at any production issues you may have and custom design a tool to solve all your problems.

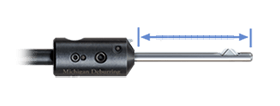

Confined Space

In this application for a 4.5 mm hole, there is a limited amount of space available in the work area. Additionally, operator input led to inconsistent results. These problems were resolved by shortening the tool and providing a fixed position blade.

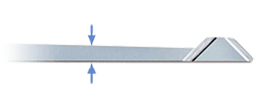

Extra Length

In this situation, extra reach was required to deburr a 3mm hole. The pilot and blade were lengthened to accommodate the requirements.

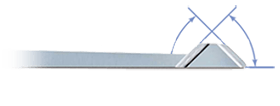

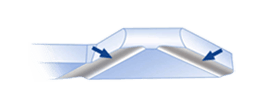

Limited Clearance

The part geometry provided very little clearance beyond the bottom of the hole on this job. The pilot was specially designed to allow the cutting edge of the blade to be moved very close to the tip of the tool.

Stainless Steel

In this stainless steel application, tool life was poor. This was solved by shortening the tool to make it more aggressive and reducing the relief angle so that the blade took less bite. The result was a more desirable light edge break and increased blade life.

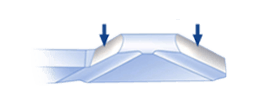

Tool Breakage

In this case, a shoulder close to the edge of the hole was causing tool breakage. The tool was shortened to provide a more aggressive cut, and a fixed position blade with a lower profile prevented the blade from hitting the shoulder.